Subcontracting

In subcontracting, you employ an external party to carry out tasks for your organization, especially manufacturing.

Subcontracting is a type of job contract that seeks to outsource certain kinds of work to other companies. It allows work on more than one phase of the project to be done at once, often leading to quicker completion.

Subcontracting is practised by various industries. For example, manufacturers who make several products from complex components subcontract certain components and package them at their facilities.

If your business involves outsourcing certain processes to a third-party Supplier where you supply the raw materials and the third party does the labour/production, you can track this by using the subcontracting feature of iVendNext.

1. How to Set up Subcontracting

Create a Service Item (Non-stock Item). It represents the service cost of the subcontracted operation.

Create separate Items for the unprocessed and the processed product. For example, if you supply unpainted X to your Supplier and the Supplier returns you X, you can create two Items: “X-unpainted” and “X”.

Create a Warehouse for your Supplier so that you can keep track of Items supplied. (You may supply a month's worth of Items in one go).

For the processed Item, in the Item master, enable “Supply Raw Materials for Purchase”.

1.1 Creating a BOM

Make a Bill Of Materials for the processed Item, with the unprocessed Items as sub-items. Let's consider a simple example, where you manufacture a pen. The processed pen will be named under the Bill of Materials(BOM), whereas, the nib, plastic, ink, etc. will be categorized as sub-items. This BOM will be without Operations if all of the production work is done by a third party.

To access the BOM list, go to: Home > Manufacturing.

Then under the Bill of Materials Section click on the Bill of Materials shortcut.

Click on the Add BOM button. This should open the BOM Creation Screen. The BOM Creation settings are split across the following tabs:

Production Item

Operations

Scrap and Process Loss

More Info

Website

The Production Item Tab

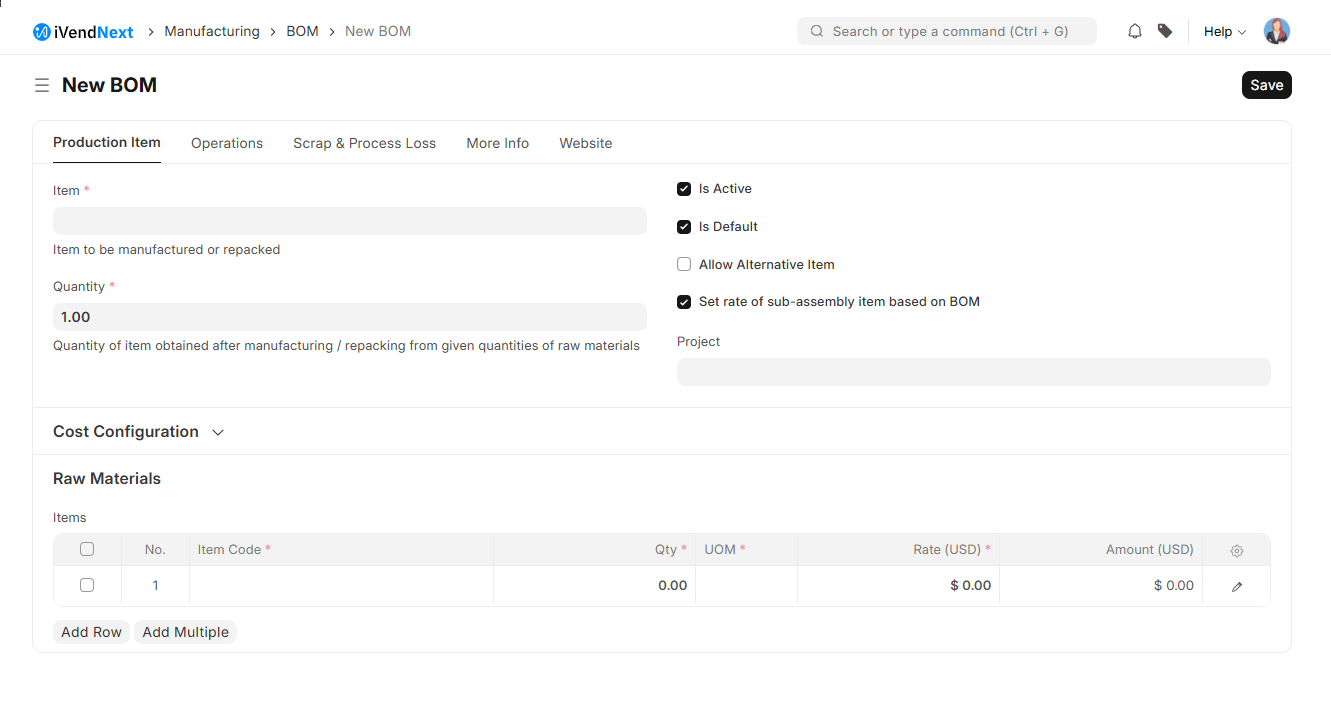

A screenshot of the Production Item Tab is pasted below:

The Operations Tab

A screenshot of the Operations Tab is pasted below:

The Scrap and Process Loss Tab

A screenshot of the Scrap and Process Loss Tab is pasted below:

The More Info Tab

A screenshot of the More Info Tab is pasted below:

The Website Tab

A screenshot of the Website Tab is pasted below:

Once a BOM is submitted, it cannot be edited. You can only cancel the existing, duplicate it and submit another one. A BOM is also linked to multiple places in the Manufacturing module, so making changes to it can be time-consuming and tedious. Hence it is a good practice to carefully think and fill out the BOMs before submitting.

1.2 Creating a Purchase Order

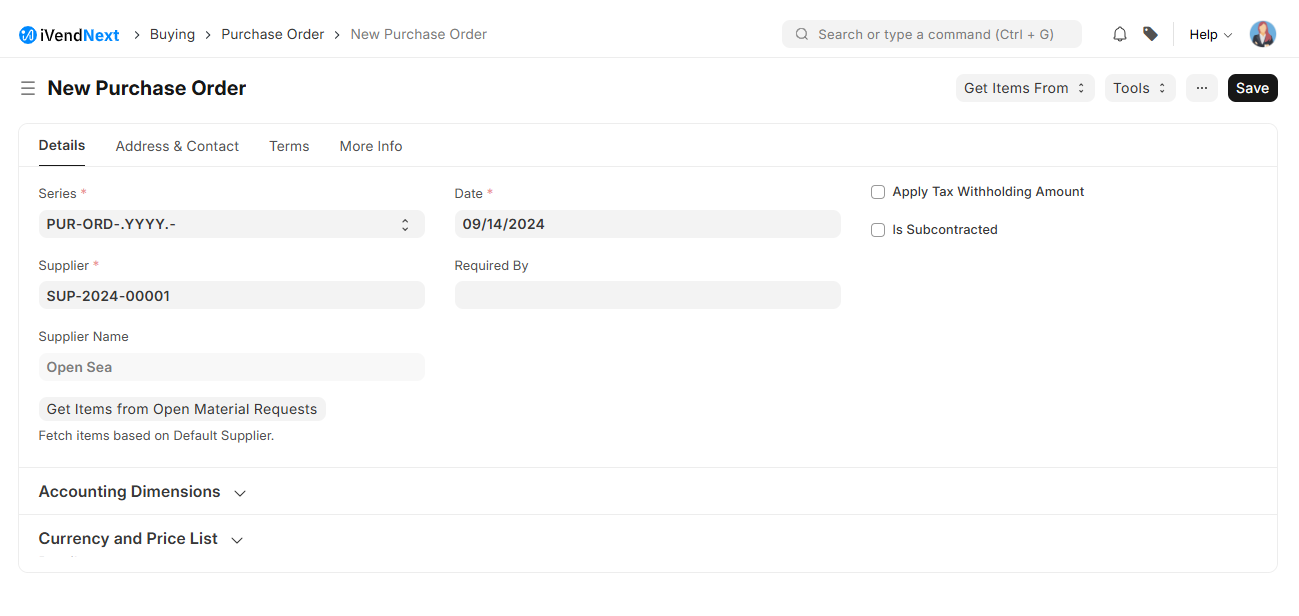

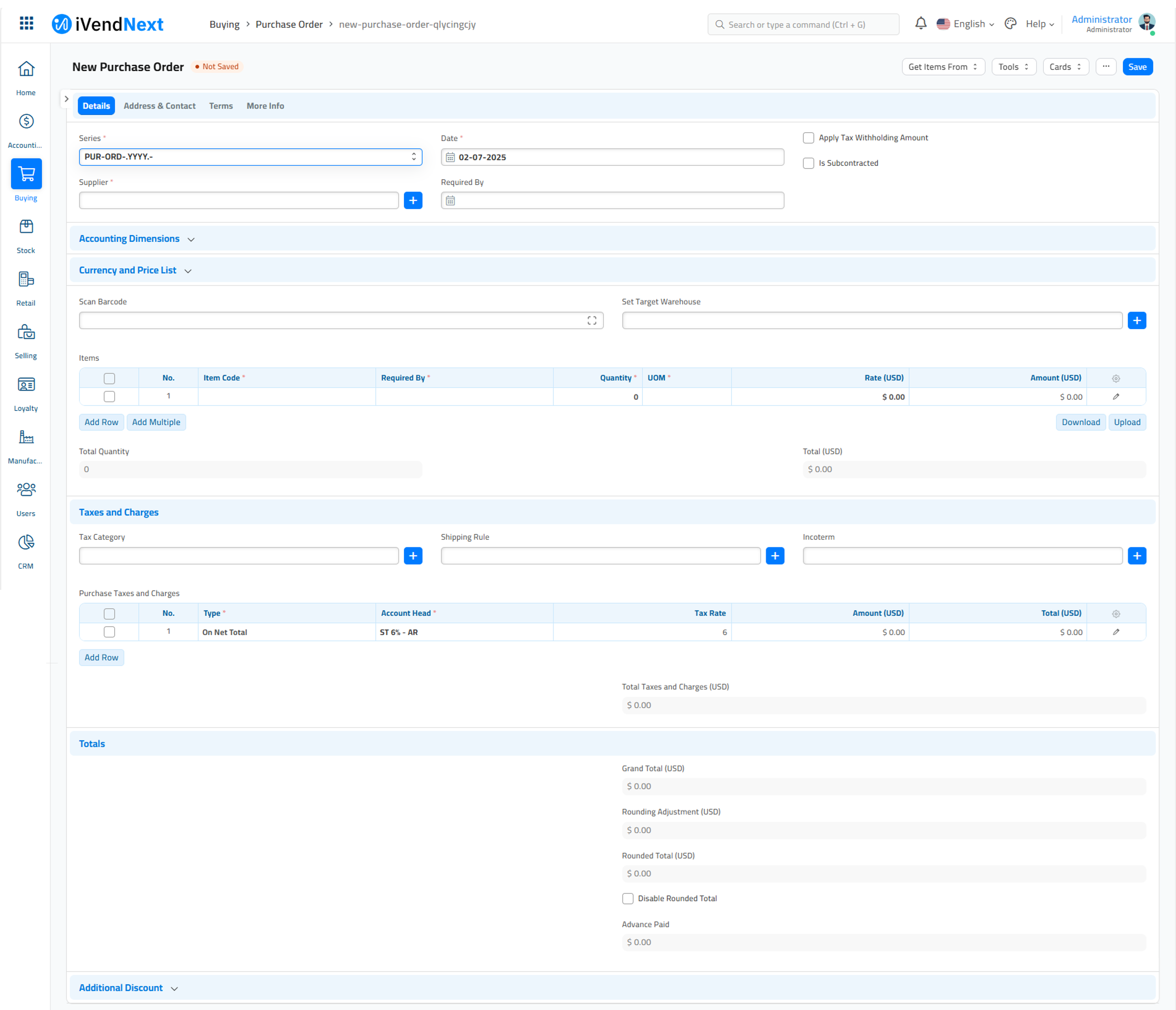

Make a Subcontract Purchase Order for the Service Item and select the Finished Good Item, the one for which you've created a BOM.

Enable the "Is Subcontracted" since this Purchase Order is for Subcontracting.

Here the Rate field value of the Items table in the Purchase Order will be the service cost you have agreed with the third party or the Supplier.

After filling in the details, Save and Submit the Purchase Order.

1.3 Creating a Subcontracting Order

Make a Subcontracting Order for the Purchase Order by clicking on Create > Subcontracting Order. When you “Save”, in the “Raw Materials Supplied”, all your un-processed Items will be updated based on your Bill of Materials. You can also select the Warehouse in which the raw materials would be reserved for subcontracting under Reserve Warehouse.

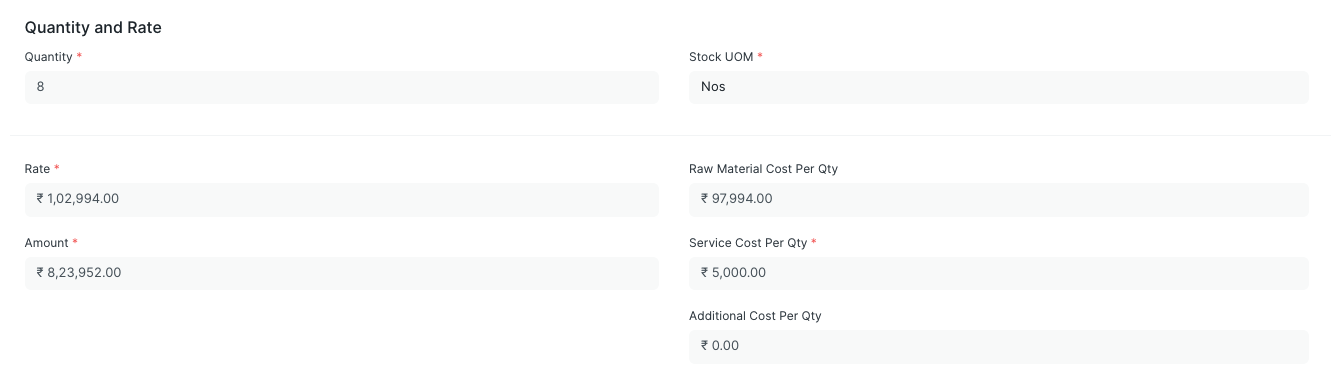

The costs involved with the subcontracting process should be recorded in the Rate field of the Items table in the Subcontracting Order.

Let's say that we are providing the subcontractor with the following items:

8 Motherboards

8 Processors

16 RAMs

8 Hard Disks

8 Cabinets

The cost for one CPU including Raw Materials and Service Costs is 1,02,994 and the total cost for all CPUs is 8,23,952

From a Subcontracting Order, select the raw materials to transfer to the subcontractor.

Once the Subcontracting Order is submitted, you can view the reserved quantity of the item from the item dashboard as well.

1.4 Creating Stock Entry to Transfer Raw Materials

Now that the raw materials are reserved, make a Stock Entry and deliver the raw material Items to your Supplier.

In the Subcontracting Order, click on Transfer > Material to Supplier. Set the Source and Target Warehouses. The Stock Entry will be of type 'Send to Subcontractor' where you transfer from one Warehouse to another. Tick 'From BOM', select the BOM, enter the quantity, and click the Get Items button.

1.5 Creating a Subcontracting Receipt to receive the Finished and Scrap items

Receive the Items from your Supplier using a Subcontracting Receipt. You need to enter the Supplier Warehouse from where the raw materials will be taken and finished goods will be received in the Accepted Warehouse. Consider this like a backflush for subcontracting.

Click on Create > Subcontracting Receipt from the Subcontracting Order. Set the Accepted and Supplier Warehouses. Make sure to check the “Consumed Quantity” in the “Raw Materials” table so that the correct stock is maintained at the Supplier’s end. You need to select the Supplier's Warehouse where you'll receive the finished goods.

Scrap items are fetched from the chosen Bill of Materials (BOM) for Finished Goods within the Items table. The Qty is computed using the Qty of the Finished Good Item, while the Rate is determined by either the Valuation Rate or the Scrap Rate specified in the BOM.

1.6 Creating a Purchase Receipt

Back to Purchase Order, click on Create > Purchase Receipt. There will be no effect on the Stock Ledger and Accounting Ledger since both the Stock and Accounting Ledger are updated when you Submit the Subcontracting Receipt. In case you have "Purchase Taxes and Charges" the Accounting Ledger will update accordingly.

1.7 Supplier Sourced Raw Material

While creating a BOM for subcontracting, there might be a few raw materials like nuts and bolts that the Suppliers will have to procure themselves.

While creating a Stock Entry for "Transfer" from a Subcontracting Order, these items can be excluded one by one, but it is impossible to do so if you have more than 100 items.

If some raw material is sourced by the Supplier directly, then such raw materials have to be included in the BOM.

It will have zero value in BOM

In the Subcontracting Order, this raw material will not appear in Supplied Items since it is not supplied

Also, while creating a "Transfer", such items will be excluded from the Stock Entry

However, the Supplier may choose to include the supplier-provided items in their Sales Order sent to you.

2. Notes

Make sure that the “Rate” of the processed Item is the processing/service cost (excluding the raw material cost).

iVendNext will automatically add the raw material rate for your valuation purpose when you receive the finished item in your stock.

iVendNext will automatically default the 'Reserve Warehouse' in the Subcontracting Order from the BOM. If not found in the BOM, it would default it from the default Warehouse set in the Item. You can set the default Reserve Warehouse for all the Items in the Subcontracting Order from the 'Reserve Warehouse' field in the Raw Materials Supplied section.